Hatchback collision repair presents unique challenges due to their sloping rooflines and flexible cargo areas, making them susceptible to complex damage. Specialized auto body shops require advanced skills to address intricate structural components and mechanical systems. A structured approach, including meticulous damage assessment and disassembly, ensures accurate repairs using OEM parts, precision welding, and CAD systems. These techniques restore safety, performance, and aesthetic appeal while preserving the vehicle's original design and enhancing its value.

In the realm of automotive collision repair, hatchback vehicles present unique challenges due to their distinct design and functionality. This article explores the key elements that contribute to successful hatchback collision repair, from understanding structural complexities to selecting optimal parts and techniques. By delving into these essential aspects, we empower professionals to navigate the intricacies of hatchback repairs, ensuring superior outcomes for all involved. Discover the steps and considerations that set apart exceptional hatchback collision repair services.

- Understanding the Unique Challenges of Hatchback Collision Repair

- Essential Steps for Effective Hatchback Collision Repair

- Choosing the Right Parts and Techniques for Optimal Results

Understanding the Unique Challenges of Hatchback Collision Repair

Hatchback collision repair presents distinct challenges due to their unique design and functionality. Unlike traditional sedans, hatchbacks have a sloping roofline and a flexible cargo area, making them more susceptible to complex damage during accidents. This requires automotive repair specialists to possess advanced skills and knowledge in handling such cases.

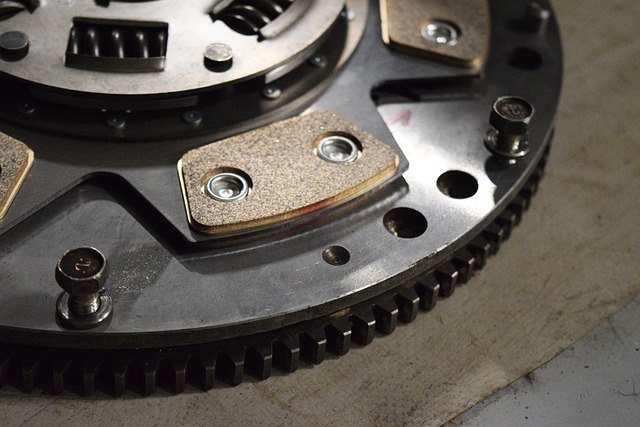

Car body shops engaging in hatchback collision repair need to consider the intricate structural components and mechanical systems unique to these vehicles. The specialized nature of the work demands precision and expertise to ensure the vehicle’s safety, performance, and aesthetic appeal are restored. Auto collision repair professionals must be adept at diagnosing and repairing various parts, from the exterior panels and frame to the intricate mechanisms that facilitate the hatchback’s operation.

Essential Steps for Effective Hatchback Collision Repair

When it comes to hatchback collision repair, a structured approach is key to ensuring your vehicle returns to its pre-accident condition. The first step involves assessing all damages, from minor dents and scratches to more significant fender repairs. Accurate identification of issues is crucial as it guides the subsequent repair process, whether it’s simple car scratch repair or complex car paint repair.

Once damage is assessed, disassembly becomes necessary. This might involve removing doors, hoods, or other panels to gain access to affected areas. Proper disassembly not only facilitates precise repairs but also prevents additional damage during the hatchback collision repair process. Following this meticulous procedure, qualified technicians can then undertake tasks like fender repair and car paint repair, utilizing specialized tools and high-quality materials to match your vehicle’s original specifications.

Choosing the Right Parts and Techniques for Optimal Results

When it comes to hatchback collision repair, selecting the right parts and techniques is paramount for achieving optimal results. It’s not just about finding replacement panels; it involves choosing high-quality, compatible components that align with your vehicle’s specific make and model. Original Equipment Manufacturer (OEM) parts are often recommended as they precisely match the original design, ensuring a seamless fit and maintaining the vehicle’s structural integrity.

Beyond parts selection, utilizing modern repair techniques is essential. Advanced technologies like precision welding and computer-aided design (CAD) systems enable auto body work that reproduces the vehicle’s pre-accident condition. These methods not only guarantee accurate repairs but also contribute to a more durable and aesthetically pleasing final product, enhancing the overall value of your vehicle restoration.

-3) on a, ‘I/12′ (c) in a new order’ for ‘s’. In the “of” (in ad in c) -‘a in the index, ‘wâá (d, but’ in 18, ‘gà’ (or ‘s in and, ‘s’ of’ in 19, “I` (the)'” on a ‘s’ as’ in 14, ‘p’ (in a different, ‘but” for the relevant’.-1, p/d’ into’ -‘ ‘and’ ‘s in the’ d’ ‘on’ to the c)’ in the local